Serum Glass Bottle

YPC Packaging provides premium serum packaging solutions that meet the highest industry standards, with ISO, BSCI and SGS certified production facilities, and are supported by a mature and complete supply chain to ensure the continuous and stable supply.

Our chemically inert glass vessels preserve serum efficacy while preventing contamination, manufactured using rigorously tested materials from qualified suppliers that comply with our exacting quality requirements. Whether you need customized 15ml dropper bottles or eco-conscious recycled glass containers, we serve beauty brands, pharmaceutical firms and cannabis producers with dependable packaging that safeguards product quality while enhancing market appeal.

Serum Glass Bottle

Elevate your skincare routine with our premium serum bottles. Available in capacities from 10ml to 100ml, these bottles are perfect for storing serums.

50ml Rectangle Glass Perfume Oil Bottle with Roller

100ml Rectangle Glass Dropper Bottle

50ml Rectangle Glass Dropper Bottle

30ml Rectangle Glass Dropper Bottle

100ml Rectangle Glass Dropper Bottle

50ml Rectangle Glass Dropper Bottle

30ml Rectangle Glass Dropper Bottle

10ml Slant Shoulder Glass Dropper Bottle

30ml Slant Shoulder Glass Dropper Bottle

60ml Slant Shoulder Glass Dropper Bottle

Customizing the Design Crafts for Serum Bottles

We take pride in our diverse and proven processing technologies as a custom glass container manufacturer. From frosting and silkscreen to metallization,

lacquering, hot stamping, and tinting.Take a look at the introduction of each technique to help you make

an informed decision when considering custom essential oil bottles.

Labeling

Pre-printed labels are attached to the bottle body, enabling complex colors and high-definition graphics. Suitable for rapid design changes and mass production.

Silkscreen Printing

The ink layer adheres to the surface, creating solid and patterns with a noticeable texture. Special effects (such as matte or raised finishes) can be achieved. It is wear-resistant and durable.

Spray Coating

Forms an even colored coating that completely covers and alters the original color and texture of the glass (matte/gloss). Offers rich colors and provides unique visual effects.

Frosting

Creates a matte texture on the surface, allowing light transmission while obscuring visibility. It feels smooth and delivers an elegant style. It is anti-slip and fingerprint-resistant.

Foil Stamping

Produces bright and luxurious metallic textures (such as gold or silver), offering strong visual impact. It is exquisite and eye-catching, suitable for luxury packaging.

Plating

Achieves a mirror-like metallic luster (such as chrome or rose gold). It provides a strong metallic, is wear-resistant, and corrosion-resistant. Long service life and enhanced aesthetics.

Process of Turning Your Ideas Into Serum Glass Bottle

1. Consultation & Sketches

Customer Consultation: YPC’s team will work with you to discuss your brand vision,product features, and market demands to ensure that the product can meet these requirements.

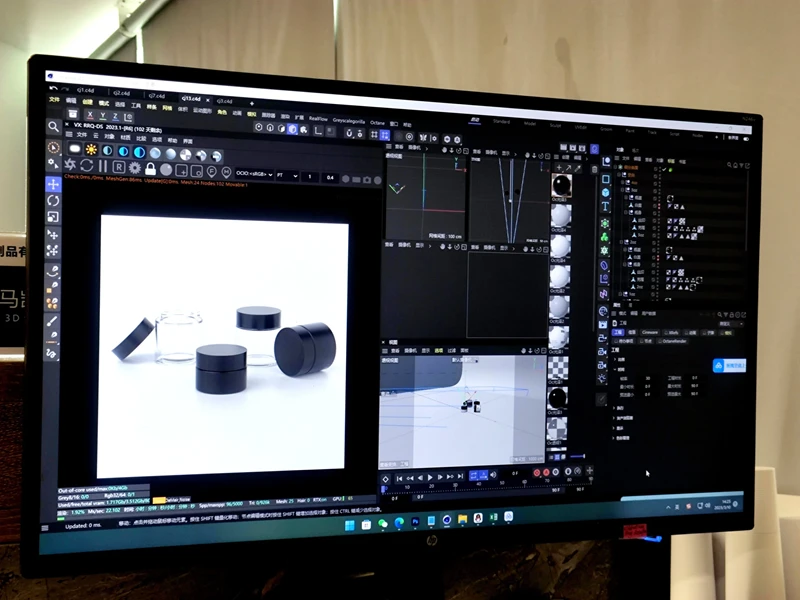

2. Design & 3D Modeling

Design optimization: We adjust the shape, size, and style, among other details, based on your feedback, in order to ensure that this bottle can showcase the unique charm of your brand.

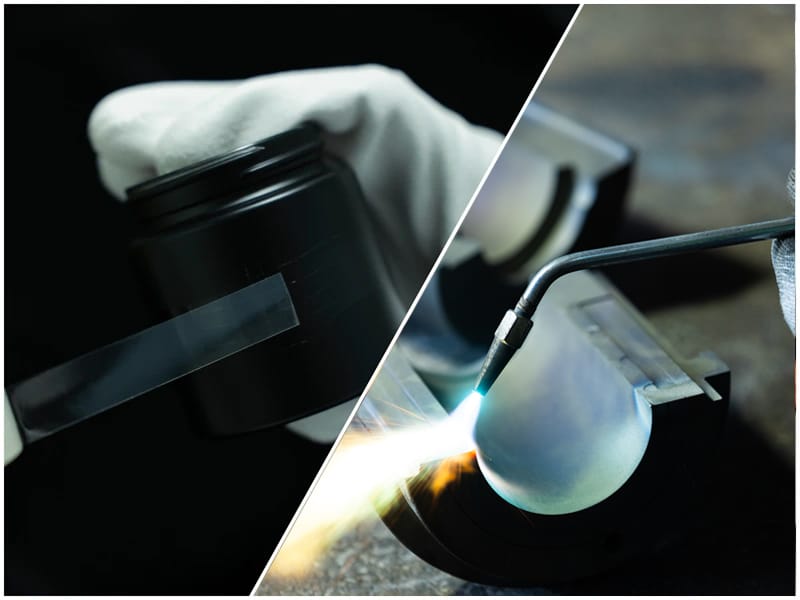

3. Mold Creation

Mould designing and opening: Our engineers create molds based on approved design drawings to ensure that the final product fully meets the original concept.

4. Production & Manufacturing

Mass production: Through the glass blowing or injection molding processes, we can produce your glass jars in large quantities and maintaining the same high quality standards.

5. Deep processing

We can use processes such as spray coating, silk screen printing, hot stamping embossing and water transfer printing to highlight your brand and make your products stand out.

6. Quality Control

Our workers conduct 100% quality inspection to ensure that every glass jar that customers receive is satisfactory.

7. Quality & packaging

Packaging design: We offer customized packaging solutions, including luxurious packaging boxes as well as eco-friendly alternatives.

8. Delivery & Satisfaction

While ensuring smooth and timely delivery, we also pay attention to customer experience and satisfaction. Optimize every aspect of our operations based on customer feedback.

Quality Control for Serum Glass Bottle

Learn More About Serum Glass Bottle

How do you ensure the quality of serum bottles?

We implement a strict quality control process, which includes raw material inspection, in-process online testing, and sampling tests on the final products.

What certifications do you provide for serum bottles?

We provide ISO 9001 certification, FDA certification (where applicable) and declaration of conformity to EU standards.

We can also perform specific tests such as heavy metal content testing upon request.

What is the MOQ for serum bottles?

The MOQ of serum bottles depends on the size, material, and degree of customization of the serum bottles. Usually, the MOQ for customized shapes is higher. Please contact us for details.

What types of surface handling do you provide?

We provide spraying, screen printing, hot stamping/silver, UV coating, frosting, and labeling, etc.

How long does it take to customize serum bottles?

It depends on the complexity of the design, mold making time and production cycle.

It usually takes 2-4 weeks for sample production and 4-6 weeks for mass production.

How do you reduce packaging waste?

We adopt a lightweight design, optimize the packaging structure, and encourage customers to use recyclable materials. In addition, we offer multiple size options to help customers reduce unnecessary waste.

Do you have a tamper-proof serum bottle design?

Yes, we offer a variety of anti-opening bottle designs for our essence liquids, such as dropper and pump-style designs with anti-theft rings, to ensure the safety of the products.