Child-resistant (CR) caps

These caps meet legal safety requirements in regulated markets by having a locking mechanism that requires a combination of movements, such as pushing and turning, to open.

Pre-roll glass tubes are premium packaging for cannabis joints, blunts, or vape cartridges, offering superior protection from physical damage and preserving freshness, potency, and flavor due to their airtight, moisture-resistant, and smell-proof properties. They present a high-end aesthetic, often come with child-resistant caps for compliance, and are customizable for branding purposes.

Our pre-roll glass tubes has a wide variety of heights and neck finishes so you can package a single mini joint up to a multipack of king size cones.

A glass tube is a long, slender container designed to hold and protect single or a few cigarettes. Its shape matches the product, making it ideal for individual use or small multi-packs.

Material is borosilicate glass, offer a premium and durable packaging solution. Known for their heat resistance and crystal clarity, they protect individual cigarettes from being crushed while showcasing the product inside.

Wider than tubes, typically featuring a defined neck and a broader body, sometimes called a “packer bottle” or “jar”. Their shape is not designed to hold individual cigarettes but rather a larger quantity or loose tobacco.

Soda lime glass material is much less expensive to produce and easier to shape than borosilicate glass, which is why it is used for mass-market products

Customizing pre-roll glass tubes is essential for brands looking to establish a strong identity, meet regulatory demands, and enhance the customer experience in the competitive cannabis market. Custom pre-roll packaging is a powerful tool for brand differentiation, creating a memorable identity through unique designs, colors, and finishes.

Pre-printed labels are attached to the bottle body, enabling complex colors and high-definition graphics. Suitable for rapid design changes and mass production.

The ink layer adheres to the surface, creating solid and patterns with a noticeable texture. Special effects (such as matte or raised finishes) can be achieved. It is wear-resistant and durable.

Forms an even colored coating that completely covers and alters the original color and texture of the glass (matte/gloss). Offers rich colors and provides unique visual effects.

Creates a matte texture on the surface, allowing light transmission while obscuring visibility. It feels smooth and delivers an elegant style. It is anti-slip and fingerprint-resistant.

Produces bright and luxurious metallic textures (such as gold or silver), offering strong visual impact. It is exquisite and eye-catching, suitable for luxury packaging.

Achieves a mirror-like metallic luster (such as chrome or rose gold). It provides a strong metallic, is wear-resistant, and corrosion-resistant. Long service life and enhanced aesthetics.

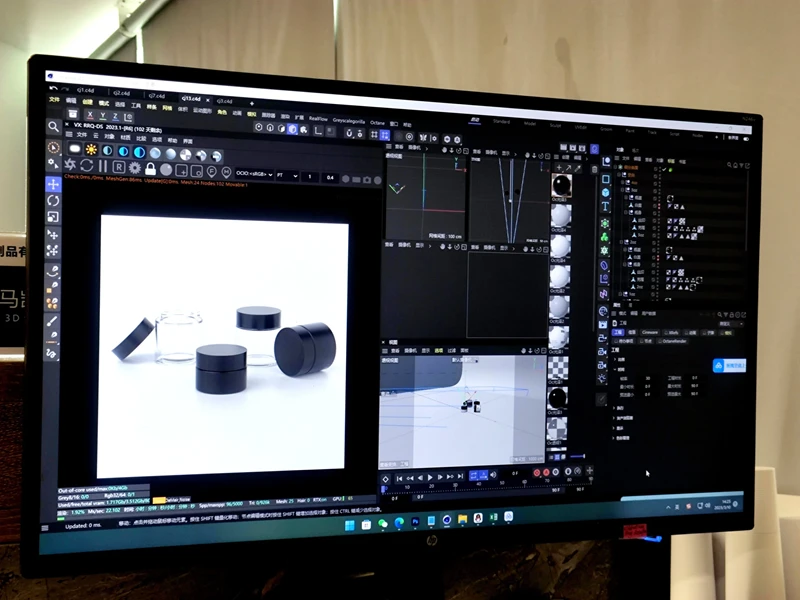

Customer Consultation: YPC’s team will work with you to discuss your brand vision,product features, and market demands to ensure that the product can meet these requirements.

Design optimization: We adjust the shape, size, and style, among other details, based on your feedback, in order to ensure that this bottle can showcase the unique charm of your brand.

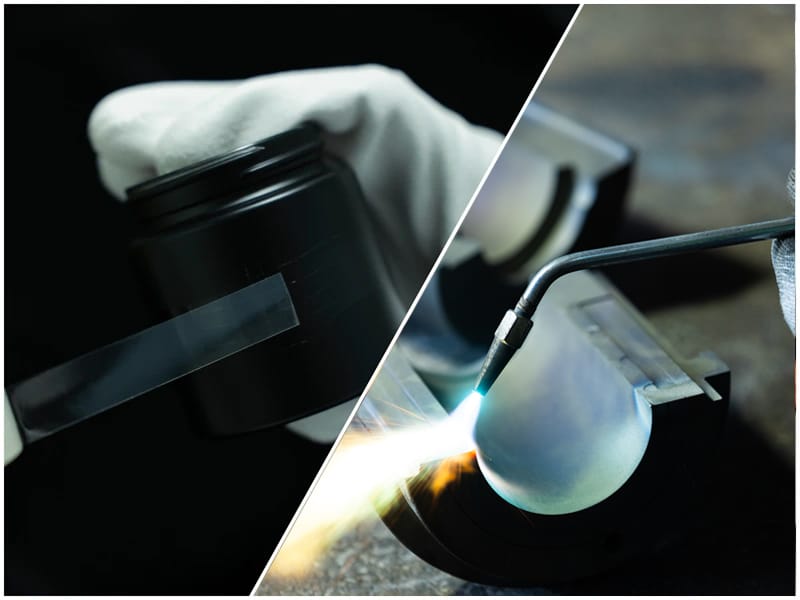

Mould designing and opening: Our engineers create molds based on approved design drawings to ensure that the final product fully meets the original concept.

Mass production: Through the glass blowing or injection molding processes, we can produce your glass jars in large quantities and maintaining the same high quality standards.

We can use processes such as spray coating, silk screen printing, hot stamping embossing and water transfer printing to highlight your brand and make your products stand out.

Our workers conduct 100% quality inspection to ensure that every glass jar that customers receive is satisfactory.

Packaging design: We offer customized packaging solutions, including luxurious packaging boxes as well as eco-friendly alternatives.

While ensuring smooth and timely delivery, we also pay attention to customer experience and satisfaction. Optimize every aspect of our operations based on customer feedback.

Glass tubes help preserve aroma and control moisture better, creating a barrier against terpene degradation and oxidation. They have a premium aesthetic and are reusable.

The right size depends on the pre-rolls’ length and amount of cannabis. Common lengths include 90mm (for smaller pre-rolls like 0.3-0.5g), 98mm (for 0.75-1g), and 116mm or 120mm (for king-sized joints or blunts). A standard diameter is around 16mm for a single joint.

We provide you child resistant caps and non child resistant cap for your choice, child resistant caps are plastic, non child resistant caps are corks, aluminum screw cap and plastic screw cap.

Yes, you can customize pre-roll tubes with a logo, branding elements, colors, and finishes using various methods, including direct printing, labels, color coating, or custom caps.

Yes, depending on their size and features, glass tubes can also be used for storing other cannabis-related products like kief, small amounts of flower, or even vape cartridges.

Glass pre-roll tubes with airtight seals are highly effective at containing the aroma of cannabis, helping to ensure discretion. The airtight seal created by the ridged child-resistant cap helps contain any smells.