Glass Foundation Bottle

Your foundation bottle is your brand’s voice. We craft premium, customizable packaging that blends protection with beauty—helping your product shine.

Choose from luxury glass or lightweight plastic designs, all made to:

Keep formulas fresh

Impress customers

Tell your brand story

Browse our collection to find packaging that sets you apart. With YPC Packaging, get more than bottles—get a growth partner.

Glass Foundation Bottle

Our glass liquid foundation glass bottles come in a variety of shapes and sizes, perfect for packaging all types of liquid foundation.

Customizing the Design Crafts fr Foundation Bottle

We take pride in our diverse and proven processing technologies as a custom glass container manufacturer. From frosting and silkscreen to metallization, lacquering, hot stamping, and tinting.Take a look at the introduction of each technique to help you make an informed decision when considering custom essential oil bottles.

Labeling

Pre-printed labels are attached to the bottle body, enabling complex colors and high-definition graphics. Suitable for rapid design changes and mass production.

Silkscreen Printing

The ink layer adheres to the surface, creating solid and patterns with a noticeable texture. Special effects (such as matte or raised finishes) can be achieved. It is wear-resistant and durable.

Spray Coating

Forms an even colored coating that completely covers and alters the original color and texture of the glass (matte/gloss). Offers rich colors and provides unique visual effects.

Frosting

Creates a matte texture on the surface, allowing light transmission while obscuring visibility. It feels smooth and delivers an elegant style. It is anti-slip and fingerprint-resistant.

Foil Stamping

Produces bright and luxurious metallic textures (such as gold or silver), offering strong visual impact. It is exquisite and eye-catching, suitable for luxury packaging.

Plating

Achieves a mirror-like metallic luster (such as chrome or rose gold). It provides a strong metallic, is wear-resistant, and corrosion-resistant. Long service life and enhanced aesthetics.

Process of Turning Your Ideas Into Glass Foundation Bottle

1. Consultation & Sketches

Customer Consultation: YPC’s team will work with you to discuss your brand vision,product features, and market demands to ensure that the product can meet these requirements.

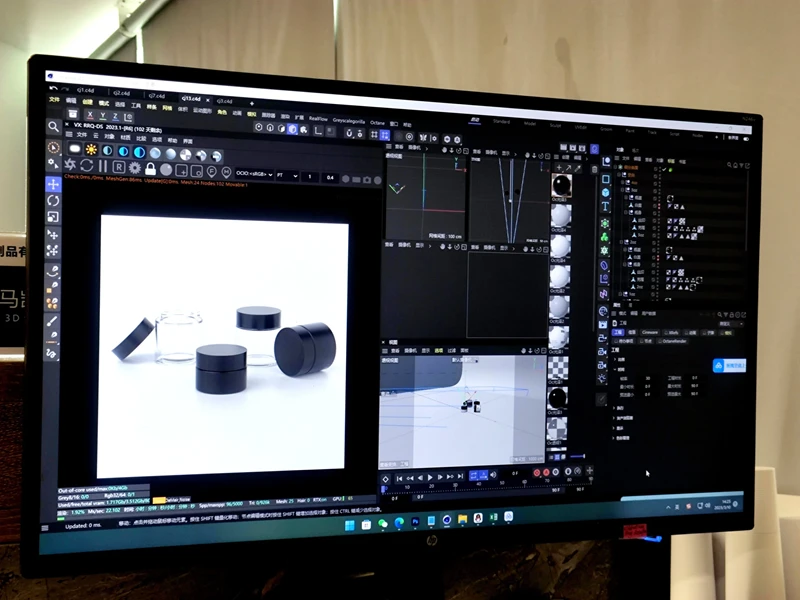

2. Design & 3D Modeling

Design optimization: We adjust the shape, size, and style, among other details, based on your feedback, in order to ensure that this bottle can showcase the unique charm of your brand.

3. Mold Creation

Mould designing and opening: Our engineers create molds based on approved design drawings to ensure that the final product fully meets the original concept.

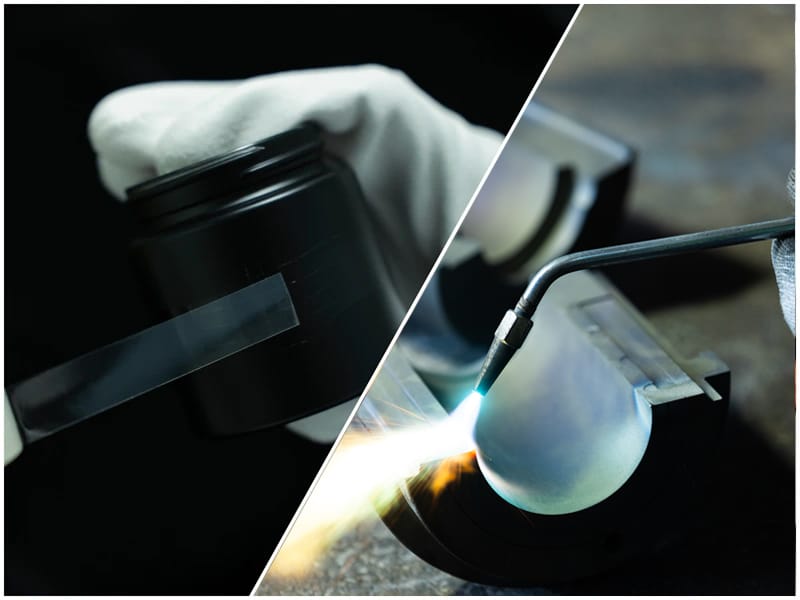

4. Production & Manufacturing

Mass production: Through the glass blowing or injection molding processes, we can produce your glass jars in large quantities and maintaining the same high quality standards.

5. Deep processing

We can use processes such as spray coating, silk screen printing, hot stamping embossing and water transfer printing to highlight your brand and make your products stand out.

6. Quality Control

Our workers conduct 100% quality inspection to ensure that every glass jar that customers receive is satisfactory.

7. Quality & packaging

Packaging design: We offer customized packaging solutions, including luxurious packaging boxes as well as eco-friendly alternatives.

8. Delivery & Satisfaction

While ensuring smooth and timely delivery, we also pay attention to customer experience and satisfaction. Optimize every aspect of our operations based on customer feedback.

Quality Contral for Glass Foundation Bottle

Learn More About Glass Foundation Bottle

What materials are your foundation bottles made of?

The material of our foundation bottles is glass. Glass can effectively preserve the ingredients of the lotion, is corrosion-resistant, eco- friendly and recyclable.

Can I have some samples before placing the large order??

Of course, we are happy to provide samples for our customers, please contact us to obtain samples and discuss related costs.

What sizes do your foundation glass bottles have?

We have various sizes for you to choose, from small travel sizes (10ml, 15ml, 20ml, 30ml) to medium regular sizes (50ml, 60ml) to large family sizes (100ml, 120ml, 200ml). Please check our product catalog for specific sizes.

What is the delivery time for foundation glass bottles?

The general delivery time is 30-35 days, but since delivery time varies depending on quantity, customization requirements and current production schedule, we will provide an estimated delivery time when you place an order.

Can I customize the foundation glass bottles with my logo and brand?

Of course! We offer a variety of printing options, including screen printing, hot stamping and labeling. The best choice for you depends on your design, budget and required level of detail.

Can you accept small batch orders?

Yes, the styles with available stock can accept small batch orders. If there is no stock or customization is required, please contact me to confirm the MOQ.