Glass Essential Oil Bottle

Engineered for optimal essential oil preservation, our bottles provide superior protection against light exposure, oxidation, and thermal variations that compromise oil quality.

We implement six advanced surface treatment technologies—precision frosting, high-definition silkscreen printing, protective lacquering, premium hot stamping, and UV-blocking tinting—that combine uncompromising product protection with unlimited branding possibilities. This dual-focused approach ensures every bottle maintains therapeutic potency while fulfilling distinctive market positioning requirements.

Glass Essential Oil Bottle

As a premier essential oil packaging specialist, we provide six specialized bottle varieties—dropper, spray, roller, airless pump, amber, and cannabis CRC containers.

50ml Frosted Olive Green Glass Dropper Bottle 22/415 | Sloping Shoulder Design for Luxury Serums, Face Oils & Premium Cosmetics

30ml Frosted Olive Green Glass Dropper Bottle 18/415 | Sloping Shoulder Design for Luxury Serums, CBD Oil & Premium Cosmetics

15ml Frosted Olive Green Glass Dropper Bottle 15/415 | Sloping Shoulder Design for Serums, Essential Oils & Luxury Cosmetics

30ml Yellow & Green Glass Dropper Bottle 18/410 | Cylinder Style for Essential Oils, CBD Serums & DIY Skincare

30ml Green Glass Dropper Bottle 24/410 Neck Finish | Cylinder Bottle for Essential Oils, CBD Oil & Serums

30ml Gradient Amber Glass Dropper Bottle 18/415 Neck Finish | Cylinder Style for Essential Oils, CBD Serums & DIY Skincare

Decoration Process of Glass Essential Oil Bottle

As an innovative glass packaging specialist, we master seven premium finishing techniques—frosting, silkscreen, lacquering, hot stamping, tinting, and UV coating.

Each process delivers distinct advantages, from elegant textures to enhanced functionality, ensuring your essential oil bottles achieve both exceptional beauty and optimal performance. Discover each technique’s unique benefits to create packaging that perfectly represents your brand.

Dropper Bottles

Dropper bottles allow precise dosing, making them ideal for essential oils used in aromatherapy, skincare, or healing treatments. Their controlled dispensing is perfect for adding oils to diffusers or applying small amounts directly to the skin.

Spray Bottles

The spray bottle is perfect for home fragrance, cleaning solutions, or personal sprays. It makes it easy to apply diluted essential oils as a room spray, body spray, or surface cleaner, or to create a personalized fragrance blend.

Roller Bottles

Roller bottles are perfect for on-the-go applications, such as personal fragrances or topical essential oil blends. They allow for easy, controlled application to pulse points, ideal for relaxation, energy boosts, or skin treatments like headaches or stress relief.

Airless Pump Bottles

Airless pump bottles are suited for skincare products, as they protect essential oil blends from air exposure, keeping them fresh. They’re ideal for lotions, serums, or oil blends that need clean, precise dispensing without contamination or oxidation.

Cannabis Dropper Bottles

Cannabis/CBD dropper bottles with child-resistant caps ensure both safety and precision. Designed to prevent accidental access, these bottles offer secure storage for CBD oils while allowing users to dispense the right amount, making them ideal for cannabis products.

Amber Bottles

Amber bottles provide UV protection, making them essential for preserving the potency of light-sensitive essential oils. They’re ideal for storing oils in bulk or in smaller quantities, protecting against light degradation, ensuring long-term efficacy and stability.

Customizing the Design Crafts for Essential Oil Bottles

We take pride in our diverse and proven processing technologies as a custom glass container manufacturer. From frosting and silkscreen to metallization, lacquering, hot stamping, and tinting.Take a look at the introduction of each technique to help you make an informed decision when considering custom essential oil bottles.

Labeling

Pre-printed labels are attached to the bottle body, enabling complex colors and high-definition graphics. Suitable for rapid design changes and mass production.

Silkscreen Printing

The ink layer adheres to the surface, creating solid and patterns with a noticeable texture. Special effects (such as matte or raised finishes) can be achieved. It is wear-resistant and durable.

Spray Coating

Forms an even colored coating that completely covers and alters the original color and texture of the glass (matte/gloss). Offers rich colors and provides unique visual effects.

Frosting

Creates a matte texture on the surface, allowing light transmission while obscuring visibility. It feels smooth and delivers an elegant style. It is anti-slip and fingerprint-resistant.

Foil Stamping

Produces bright and luxurious metallic textures (such as gold or silver), offering strong visual impact. It is exquisite and eye-catching, suitable for luxury packaging.

Plating

Achieves a mirror-like metallic luster (such as chrome or rose gold). It provides a strong metallic, is wear-resistant, and corrosion-resistant. Long service life and enhanced aesthetics.

Process of Turning Your Ideas into Tangible Glass Essential Oil Bottle

1. Consultation & Sketches

Customer Consultation: YPC’s team will work with you to discuss your brand vision,product features, and market demands to ensure that the product can meet these requirements.

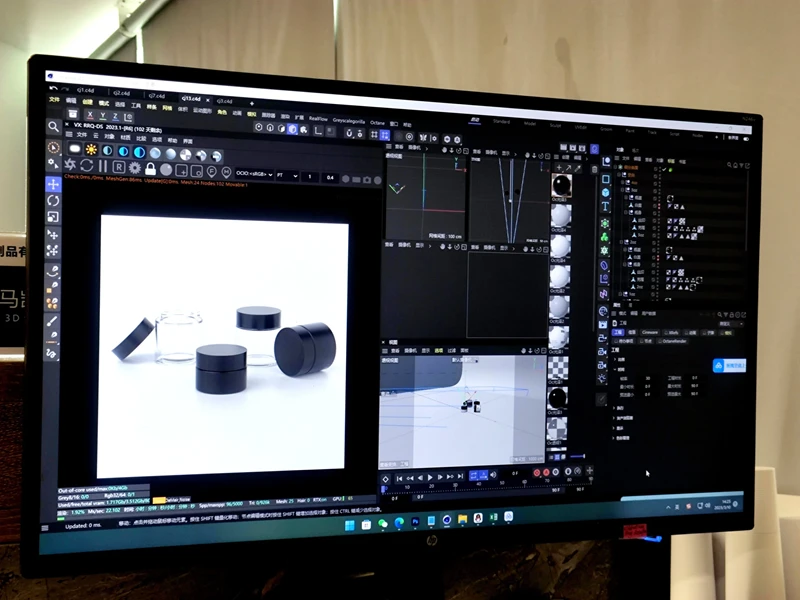

2. Design & 3D Modeling

Design optimization: We adjust the shape, size, and style, among other details, based on your feedback, in order to ensure that this bottle can showcase the unique charm of your brand.

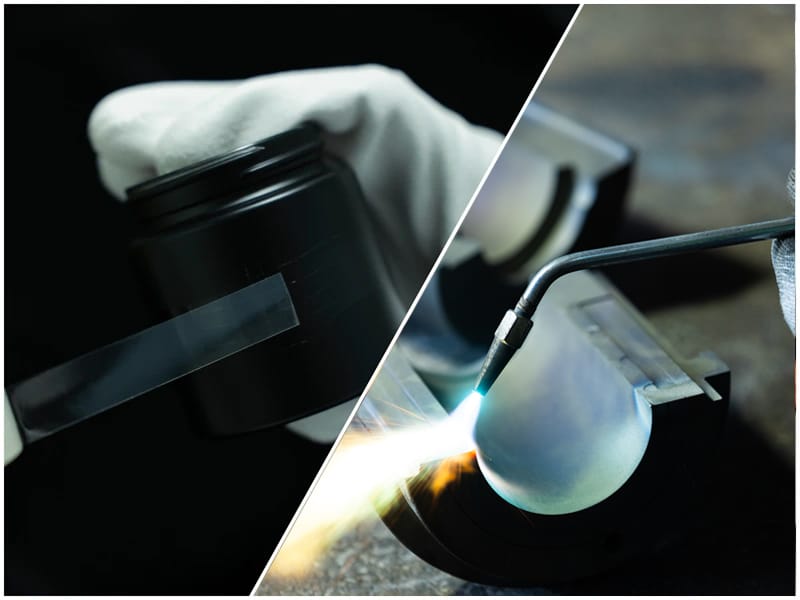

3. Mold Creation

Mould designing and opening: Our engineers create molds based on approved design drawings to ensure that the final product fully meets the original concept.

4. Production & Manufacturing

Mass production: Through the glass blowing or injection molding processes, we can produce your glass jars in large quantities and maintaining the same high quality standards.

5. Deep processing

We can use processes such as spray coating, silk screen printing, hot stamping embossing and water transfer printing to highlight your brand and make your products stand out.

6. Quality Control

Our workers conduct 100% quality inspection to ensure that every glass jar that customers receive is satisfactory.

7. Quality & packaging

Packaging design: We offer customized packaging solutions, including luxurious packaging boxes as well as eco-friendly alternatives.

8. Delivery & Satisfaction

While ensuring smooth and timely delivery, we also pay attention to customer experience and satisfaction. Optimize every aspect of our operations based on customer feedback.

Quality Control for Glass Essential Oil Bottle

Learn More About Glass Essential Oil Bottle

How to prevent the evaporation and leakage of essential oils?

For example, the dropper bottle: glass dropper + inner liner + threaded cap, triple sealing. The ball-shaped bottle: the ball fits precisely with the bottle mouth, with the tolerance controlled within a certain range. At the same time, a 40℃Celsius accelerated evaporation test was conducted.

How can the amount of essential oil be precisely controlled in the bottle?

Drop tube customer identification. Each drop is approximately 0.03 ml. The liquid output from the ball bottle can be controlled. For example, 1 revolution ≈ 0.1 ml.

How do essential oil bottles prevent ultraviolet rays?

We understand that essential oils are sensitive to light, air, and temperature, which is why we rigorously screen every material for chemical stability, purity, and safety. Our glass provides optimal UV protection.

Do you offer custom solutions for essential oil glass bottles?

Absolutely. As specialists in premium essential oil packaging, we offer comprehensive customization services including shape, color, size, logo printing, and packaging. Our custom essential oil bottles are ideal for brands looking to stand out on the shelf.

What closures are available for your glass oil bottles?

We offer various closure types including screw caps, sealed caps, dropper, pump sprayers, and roller caps. Each is designed to fit securely and dispense glass bottles for oils safely and accurately.

What are the advantages of using glass bottles for essential oils?

The essential oil glass bottle can effectively resist the erosion of UV light and chemical substances, helping to maintain the purity and efficacy of the essential oil. Moreover, this bottle is reusable and eco-friendly, aligning with the concept of sustainable packaging.

What is the MOQ for the essential oil bottles?

Stock items: No MOQ

Custom designs: MOQ varies by specification.