Glass Diffuser Bottle

Engineered for Excellence in Glass. Experience the pinnacle of fragrance presentation with our meticulously crafted Diffuser Glass Bottles. Our bottles offer exceptional chemical resistance to prevent clouding, crystal clarity for true-to-life color display, and reinforced durability for lasting elegance. Precision-formed walls ensure optimal wicking and consistent, reliable fragrance diffusion. Discover the foundation for luxury home fragrance.

Glass Diffuser Bottle

Packaging industry leaders and premium perfume brands across the spectrum – from established regional supply partners to luxury international fragrance innovators.

150ml Gradient Brown Square Glass Aromatherapy Bottle | For Essential Oils & Carrier Oils

180ml Flint Glass Aromatherapy Bottle | Large Cylinder Bottle for Carrier Oils & Massage Oils

150ml Flint Glass Aromatherapy Bottle | Large Cylinder Bottle for Essential Oils, Carrier Oils & Massage Oils

170ml Gradient Blue & Purple Glass Aromatherapy Bottle | Large Cylinder Bottle for Essential Oils, DIY Blends & Massage Oils

50ml Frosted Yellow Glass Aromatherapy Bottle | Cylinder Essential Oil Bottle for DIY Blends, Perfume & Carrier Oils

One-stop Customization Service

Transform your packaging into a masterpiece with our diverse design elements. From sleek finishes that exude elegance to vibrant accents like digital printing that demand attention, we turn ordinary storage jars into extraordinary brand statements. Add transparent windows for a sneak peek or magnified lens caps —each detail is crafted to captivate your product’s appeal.

Labeling

Pre-printed labels are attached to the bottle body, enabling complex colors and high-definition graphics. Suitable for rapid design changes and mass production.

Silkscreen Printing

The ink layer adheres to the surface, creating solid and patterns with a noticeable texture. Special effects (such as matte or raised finishes) can be achieved. It is wear-resistant and durable.

Spray Coating

Forms an even colored coating that completely covers and alters the original color and texture of the glass (matte/gloss). Offers rich colors and provides unique visual effects.

Frosting

Creates a matte texture on the surface, allowing light transmission while obscuring visibility. It feels smooth and delivers an elegant style. It is anti-slip and fingerprint-resistant.

Foil Stamping

Produces bright and luxurious metallic textures (such as gold or silver), offering strong visual impact. It is exquisite and eye-catching, suitable for luxury packaging.

Plating

Achieves a mirror-like metallic luster (such as chrome or rose gold). It provides a strong metallic, is wear-resistant, and corrosion-resistant. Long service life and enhanced aesthetics.

Process of Turning Your Ideas Into Glass Diffuser Bottle

1. Consultation & Sketches

Customer Consultation: YPC’s team will work with you to discuss your brand vision,product features, and market demands to ensure that the product can meet these requirements.

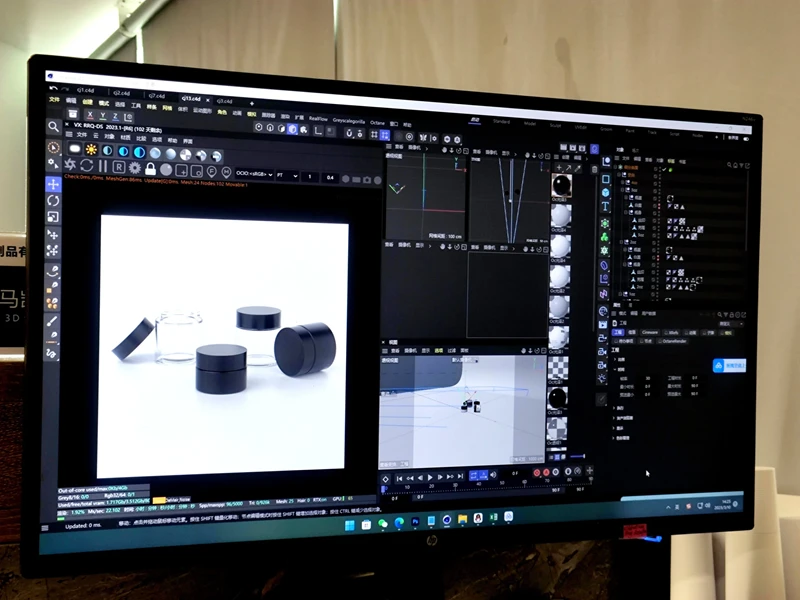

2. Design & 3D Modeling

Design optimization: We adjust the shape, size, and style, among other details, based on your feedback, in order to ensure that this bottle can showcase the unique charm of your brand.

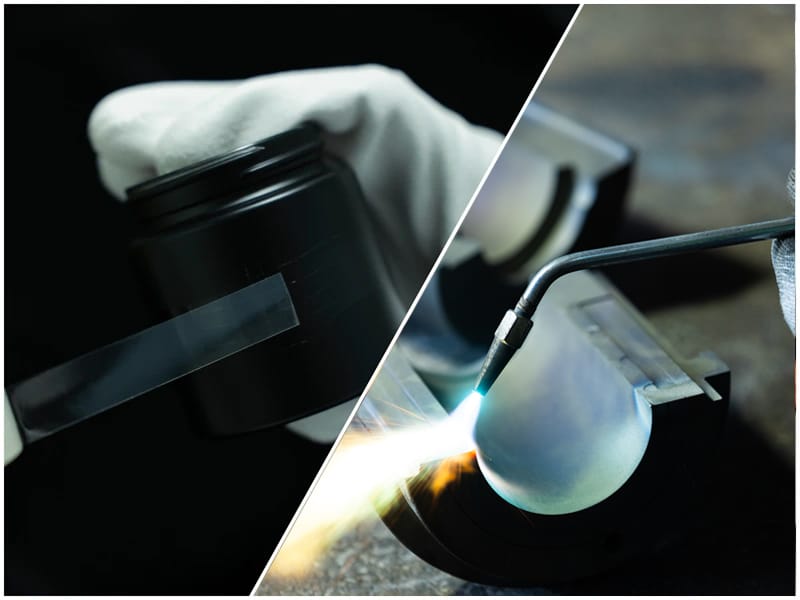

3. Mold Creation

Mould designing and opening: Our engineers create molds based on approved design drawings to ensure that the final product fully meets the original concept.

4. Production & Manufacturing

Mass production: Through the glass blowing or injection molding processes, we can produce your glass jars in large quantities and maintaining the same high quality standards.

5. Deep processing

We can use processes such as spray coating, silk screen printing, hot stamping embossing and water transfer printing to highlight your brand and make your products stand out.

6. Quality Control

Our workers conduct 100% quality inspection to ensure that every glass jar that customers receive is satisfactory.

7. Quality & packaging

Packaging design: We offer customized packaging solutions, including luxurious packaging boxes as well as eco-friendly alternatives.

8. Delivery & Satisfaction

While ensuring smooth and timely delivery, we also pay attention to customer experience and satisfaction. Optimize every aspect of our operations based on customer feedback.

Quality Control for Fragrance Glass Packaging

Learn More About Diffuser Glass Bottle

What is the primary function of a diffuser glass bottle?

Diffuser bottles store and gradually release fragrance oils through natural reed sticks or synthetic wicks, providing a consistent, long-lasting scent dispersion without heat or electricity.

What glass types do you recommend for diffuser bottles?

We recommend flint (clear) glass for visual clarity and amber glass for UV-sensitive formulations. Both options meet ASTM E438 standards for chemical resistance and durability.

What capacities are available?

Standard capacities range from 50mL to 500mL (1.7–16.9 fl oz), with custom volumes available. Popular sizes include 100mL (3.4 fl oz) and 200mL (6.8 fl oz).

Are your bottles compatible with all diffuser oils?

Yes. Our glass resists corrosion from essential oils, alcohol-based fragrances, and carrier solvents like DPG or IPM.

What closure options do you offer?

Choices include:

Wooden caps (natural/varnished)

Plastic stoppers (PP/ABS)

Euro droppers for sample-sized bottles

All ensure leak-proof seals during transit.

Can bottles be customized for branding?

Absolutely. We offer screen printing, ceramic labeling, embossing, and spray-coated finishes. MOQs start at 1,000 units for private labeling.

What certifications do your products hold?

Our bottles comply with REACH, FDA, and ISO 9001 standards. Full technical specifications and test reports are available upon request.