Cannabis Glass Jar

Take your cannabis packaging to the next level with our high-end glass jars, designed for both luxury and durability. Our versatile collection features a range of sizes and lid finishes to match your branding needs, making them ideal for marijuana flower, edibles, or concentrate storage and sale.

Cannabis Glass Jar

Perfectly sized for up to 7 grams or a half an ounce, our glass jars offer ideal storage for all your cannabis products

16OZ Straight Clear Glass Jar with Childproof Lid

8OZ Straight Amber Glass Jar with Childproof Lid

8oz straight-sided matte black glass jar with child-safe lid.

8OZ Straight Clear Glass Jar with childproof lid

10OZ Straight Childproof Glass Jar Black–57mm

10OZ Straight Glass Jar -57mm

6OZ Straight Glass Jar -53mm

5OZ Straight Childproof Glass Jar Matt Black -53mm

5OZ Straight Glass Jar — Eighth

4OZ Straight Childproof Glass Jar Matt Black

4OZ Straight Childproof Glass Jar Opal White

4OZ Straight Childproof Glass Jar Black-53mm

4OZ Straight Glass Jar — 53mm

3OZ Straight Childproof Glass Jar Matt Black –53mm

3OZ Heavy Base Straight Glass Jar –53mm

3OZ Straight Glass Jar –53mm

3.5OZ Straight Childproof Glass Jar Matt Black –53mm

3.5OZ Heavy Base Straight Glass Jar — 53mm

3.5OZ Straight Glass Jar — 53mm

2OZ Straight Glass Jar — 53mm

Customizing the Cannabis Jar Design Crafts to Enhance your Brand Identity

Transform your packaging into a masterpiece with our diverse design elements. From sleek finishes that exude elegance to vibrant accents like digital printing that demand attention, we turn ordinary storage jars into extraordinary brand statements. Add transparent windows for a sneak peek or magnified lens caps —each detail is crafted to captivate your product’s appeal.

Labeling

Pre-printed labels are attached to the bottle body, enabling complex colors and high-definition graphics. Suitable for rapid design changes and mass production.

Silkscreen Printing

The ink layer adheres to the surface, creating solid and patterns with a noticeable texture. Special effects (such as matte or raised finishes) can be achieved. It is wear-resistant and durable.

Spray Coating

Forms an even colored coating that completely covers and alters the original color and texture of the glass (matte/gloss). Offers rich colors and provides unique visual effects.

Frosting

Creates a matte texture on the surface, allowing light transmission while obscuring visibility. It feels smooth and delivers an elegant style. It is anti-slip and fingerprint-resistant.

Foil Stamping

Produces bright and luxurious metallic textures (such as gold or silver), offering strong visual impact. It is exquisite and eye-catching, suitable for luxury packaging.

Plating

Achieves a mirror-like metallic luster (such as chrome or rose gold). It provides a strong metallic, is wear-resistant, and corrosion-resistant. Long service life and enhanced aesthetics.

From concept to delivery, one-stop glass packaging customization solutions

1. Consultation & Sketches

Customer Consultation: YPC’s team will work with you to discuss your brand vision,product features, and market demands to ensure that the product can meet these requirements.

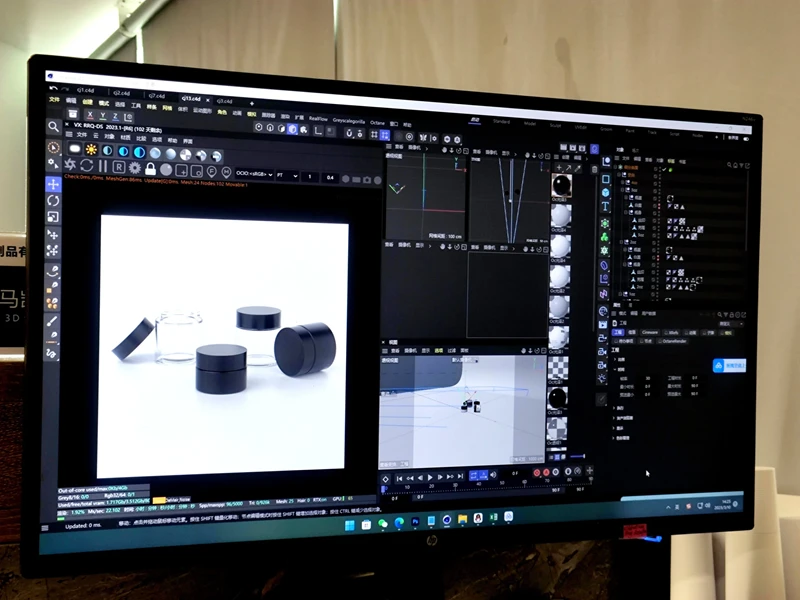

2. Design & 3D Modeling

Design optimization: We adjust the shape, size, and style, among other details, based on your feedback, in order to ensure that this bottle can showcase the unique charm of your brand.

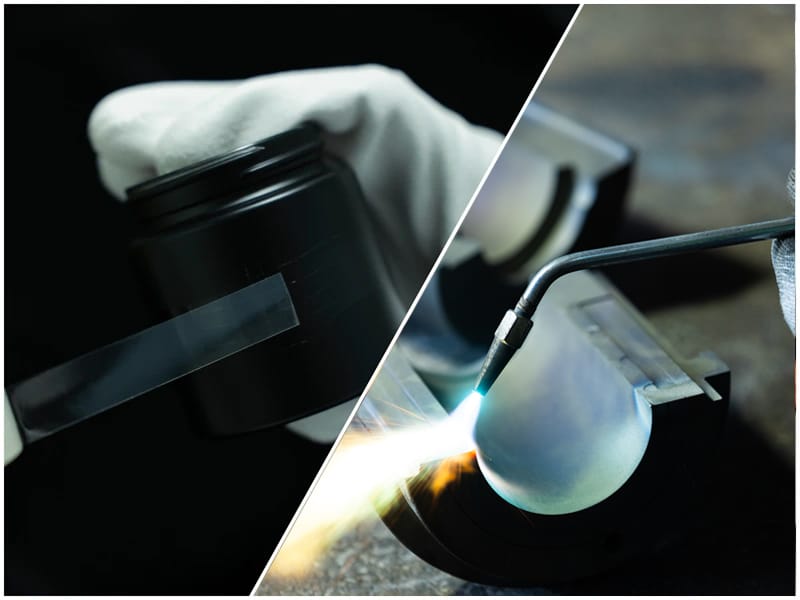

3. Mold Creation

Mould designing and opening: Our engineers create molds based on approved design drawings to ensure that the final product fully meets the original concept.

4. Production & Manufacturing

Mass production: Through the glass blowing or injection molding processes, we can produce your glass jars in large quantities and maintaining the same high quality standards.

5. Deep processing

We can use processes such as spray coating, silk screen printing, hot stamping embossing and water transfer printing to highlight your brand and make your products stand out.

6. Quality Control

Our workers conduct 100% quality inspection to ensure that every glass jar that customers receive is satisfactory.

7. Quality & packaging

Packaging design: We offer customized packaging solutions, including luxurious packaging boxes as well as eco-friendly alternatives.

8. Delivery & Satisfaction

While ensuring smooth and timely delivery, we also pay attention to customer experience and satisfaction. Optimize every aspect of our operations based on customer feedback.

Quality Control for Cannabis Glass Packaging

Learn More About Cannabis Glass Jar

Why choose glass jars for cannabis storage?

Airtight Seal: Airtight glass jars, particularly those with liners, create an enclosed environment that minimizes air exchange, a key factor in cannabis degradation.

Neutral Material: Glass is non-reactive and won’t impart unwanted flavors or chemicals into your flower, ensuring a clean and consistent taste experience.

How do I submit designs for my personalized weed jars?

Submit your brand artwork in AI, EPS, TIF, PSD or 300+ DPI PDF formats. We’ll provide customized templates and technical specs to ensure flawless print reproduction.

What should be considered when designing custom cannabis packaging?

*Compliance: Make sure the design follows all state and local regulations, including child-resistant features and labeling requirements.

*Target Audience: Consider the target demographic and their preferences to create a design that resonates with them.

*Functionality: Ensure the jars are easy to open, reseal, and convenient for consumers.

*Sustainability: Explore eco-friendly materials and design choices to appeal to environmentally conscious consumers.

*Quality: Invest in high-quality materials and printing techniques for a premium look and durability.

What is a Dram?

A dram is an old-fashioned unit of measurement rarely used in packaging today. To put it in perspective, one dram equals about 8 fluid ounces of water or roughly 29.57 milliliters (ml).

Are your cannabis glass jars airtight?

Cannabis products naturally emit a potent herbal aroma and are prone to drying out, which can degrade their quality. YPC Packaging provides airtight solutions that preserve freshness longer while effectively containing odors during storage.

What size glass jar should I use for my cannabis flowers?

*For smaller amounts, such as an eighth (3.5 grams), a 60ml / 2oz jar is a common choice.

*For larger quantities, like a quarter (7 grams), a 120ml / 4oz jar is often suitable.

*If you’re storing even more, consider a 180ml / 6oz jar for a half ounce (14g) or a 240ml / 8oz jar for a full ounce (28g).

Are special glass jars with UV protection needed?

While not strictly essential, UV-protected jars (like amber or opaque glass or spray coating glass) are highly recommended, particularly for long-term storage or if the jars are kept in areas exposed to light.

UV rays can degrade THC and other cannabinoids, reducing potency and altering the flavor, according to Fab CBD.

If using clear glass jars, ensure they are stored in a cool, dark place away from direct sunlight or bright artificial lights.