Crystal Clear Glass:

Crafted from pristine, transparent glass. Showcase your candle’s true color and luminosity for a clean, modern presentation.

Premium Glass Candle Jars: Where Purity Meets Performance

Illuminate with Uncompromising Quality. Our meticulously crafted Glass Candle Jars are engineered for discerning candle makers. Featuring exceptionally clear, high-purity glass, our jars offer unparalleled brilliance to showcase your candles’ true glow and color. Rigorously tested for superior thermal shock resistance and consistent thickness, they ensure safety, durability, and a flawless burning experience. Elevate your brand with packaging that reflects excellence – inside and out.

Leading packaging companies and renowned fragrance brands worldwide – from agile regional suppliers to iconic global houses.

Transform your packaging into a masterpiece with our diverse design elements. From sleek finishes that exude elegance to vibrant accents like digital printing that demand attention, we turn ordinary storage jars into extraordinary brand statements. Add transparent windows for a sneak peek or magnified lens caps —each detail is crafted to captivate your product’s appeal.

Pre-printed labels are attached to the bottle body, enabling complex colors and high-definition graphics. Suitable for rapid design changes and mass production.

The ink layer adheres to the surface, creating solid and patterns with a noticeable texture. Special effects (such as matte or raised finishes) can be achieved. It is wear-resistant and durable.

Forms an even colored coating that completely covers and alters the original color and texture of the glass (matte/gloss). Offers rich colors and provides unique visual effects.

Creates a matte texture on the surface, allowing light transmission while obscuring visibility. It feels smooth and delivers an elegant style. It is anti-slip and fingerprint-resistant.

Produces bright and luxurious metallic textures (such as gold or silver), offering strong visual impact. It is exquisite and eye-catching, suitable for luxury packaging.

Achieves a mirror-like metallic luster (such as chrome or rose gold). It provides a strong metallic, is wear-resistant, and corrosion-resistant. Long service life and enhanced aesthetics.

Customer Consultation: YPC’s team will work with you to discuss your brand vision,product features, and market demands to ensure that the product can meet these requirements.

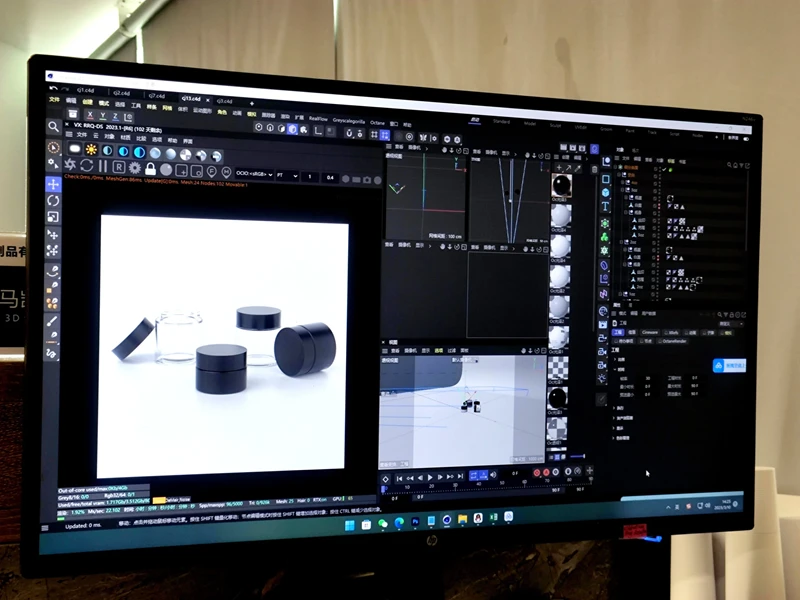

Design optimization: We adjust the shape, size, and style, among other details, based on your feedback, in order to ensure that this bottle can showcase the unique charm of your brand.

Mould designing and opening: Our engineers create molds based on approved design drawings to ensure that the final product fully meets the original concept.

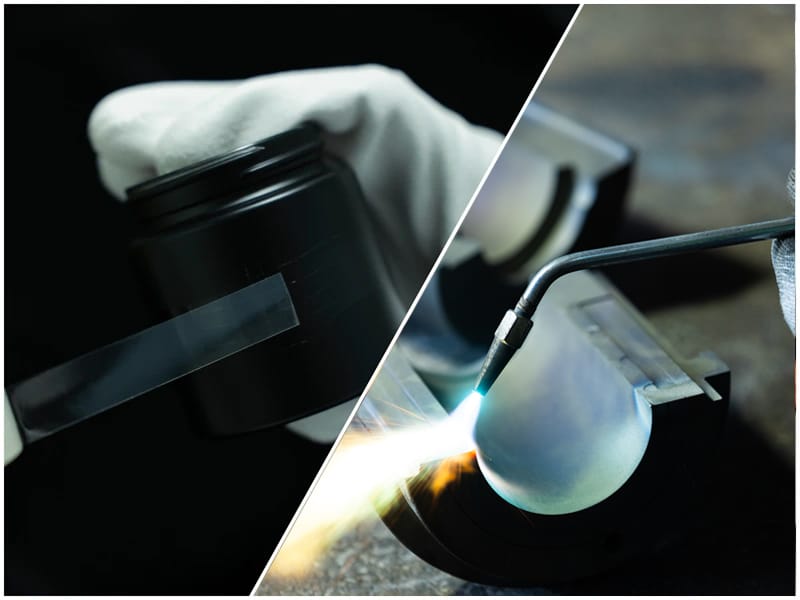

Mass production: Through the glass blowing or injection molding processes, we can produce your glass jars in large quantities and maintaining the same high quality standards.

We can use processes such as spray coating, silk screen printing, hot stamping embossing and water transfer printing to highlight your brand and make your products stand out.

Our workers conduct 100% quality inspection to ensure that every glass jar that customers receive is satisfactory.

Packaging design: We offer customized packaging solutions, including luxurious packaging boxes as well as eco-friendly alternatives.

While ensuring smooth and timely delivery, we also pay attention to customer experience and satisfaction. Optimize every aspect of our operations based on customer feedback.

We use high-purity glass for superior thermal shock resistance (withstands up to 500°F/260°C), ensuring safety during candle burning and preventing cracks or leaks.

Yes. Our jars are rigorously tested with soy, paraffin, coconut, and beeswax blends. Uniform thickness prevents hotspots, optimizing burn performance.

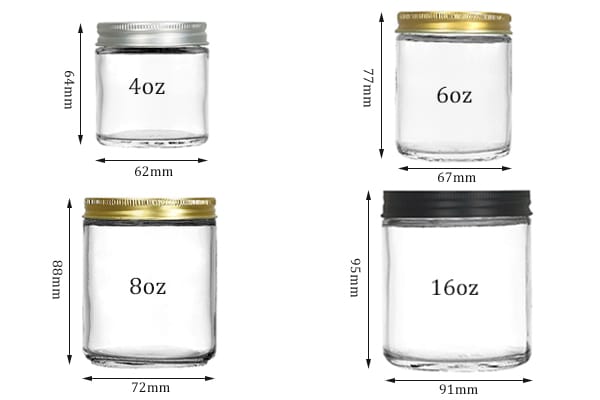

Standard capacities range from 4oz to 32oz (120ml–950ml), with custom sizing available. Popular options include: 8oz (227g), 12oz (340g), and 16oz (454g).

Absolutely. Choose from matte/glossy coatings, silk-screen printing, embossed logos, or colored glass. MOQs start at 5,000 units for custom designs.

Yes. Options include metal screw tops, wooden lids, cork stoppers, and plastic seals—all designed for airtight fragrance preservation and stackable shipping.

Jars are shipped in reinforced, compartmentalized cartons with bubble wrap/foam inserts. Breakage rates are maintained below 0.5% through our packaging protocol.

Our jars comply with FDAstandards for food-contact safety. Each batch undergoes SGS-tested thermal shock and lead/cadmium checks.CE certification and CA ROP65 certified.