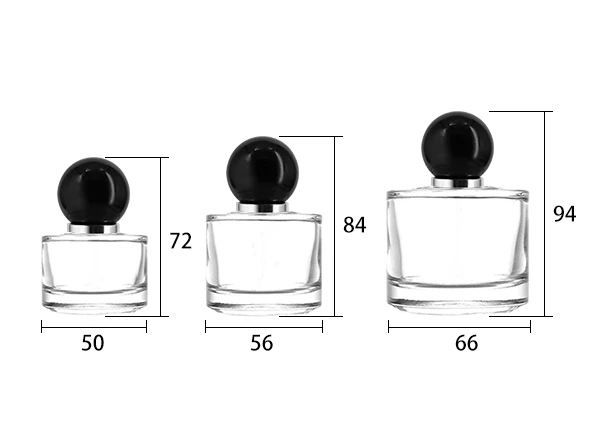

30ml | Compact & Portable

Ideal for travel, sampling, or limited-edition fragrances.

Perfect for trying new scents or niche perfumes.

Glass Perfume Bottles: Where Excellence Meets Elegance

Experience the pinnacle of glass craftsmanship. Our premium Glass Perfume Bottles are engineered from exceptionally pure, optically clear glass, ensuring flawless transparency and brilliant product presentation. Renowned for superior structural integrity, chemical inertness, and precision finishing, our bottles preserve fragrance integrity while elevating your brand perception. Discover packaging that defines luxury through material excellence.

We partner with packaging specialists and global brand owners, ranging from innovative regional suppliers to premium international fragrance houses.

We take pride in our diverse and proven processing technologies as a custom glass container manufacturer. From frosting and silkscreen to metallization,

lacquering, hot stamping, and tinting.Take a look at the introduction of each technique to help you make

an informed decision when considering custom essential oil bottles.

Pre-printed labels are attached to the bottle body, enabling complex colors and high-definition graphics. Suitable for rapid design changes and mass production.

The ink layer adheres to the surface, creating solid and patterns with a noticeable texture. Special effects (such as matte or raised finishes) can be achieved. It is wear-resistant and durable.

Forms an even colored coating that completely covers and alters the original color and texture of the glass (matte/gloss). Offers rich colors and provides unique visual effects.

Creates a matte texture on the surface, allowing light transmission while obscuring visibility. It feels smooth and delivers an elegant style. It is anti-slip and fingerprint-resistant.

Produces bright and luxurious metallic textures (such as gold or silver), offering strong visual impact. It is exquisite and eye-catching, suitable for luxury packaging.

Achieves a mirror-like metallic luster (such as chrome or rose gold). It provides a strong metallic, is wear-resistant, and corrosion-resistant. Long service life and enhanced aesthetics.

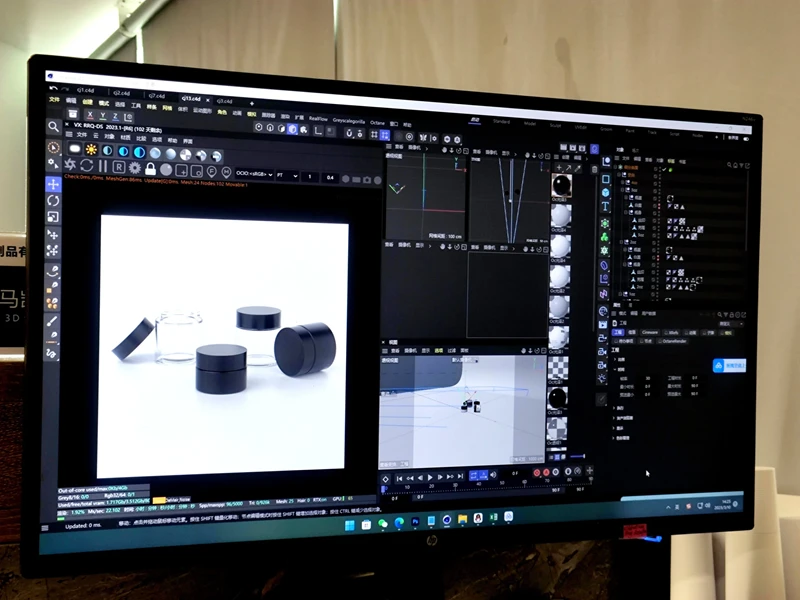

Customer Consultation: YPC’s team will work with you to discuss your brand vision,product features, and market demands to ensure that the product can meet these requirements.

Design optimization: We adjust the shape, size, and style, among other details, based on your feedback, in order to ensure that this bottle can showcase the unique charm of your brand.

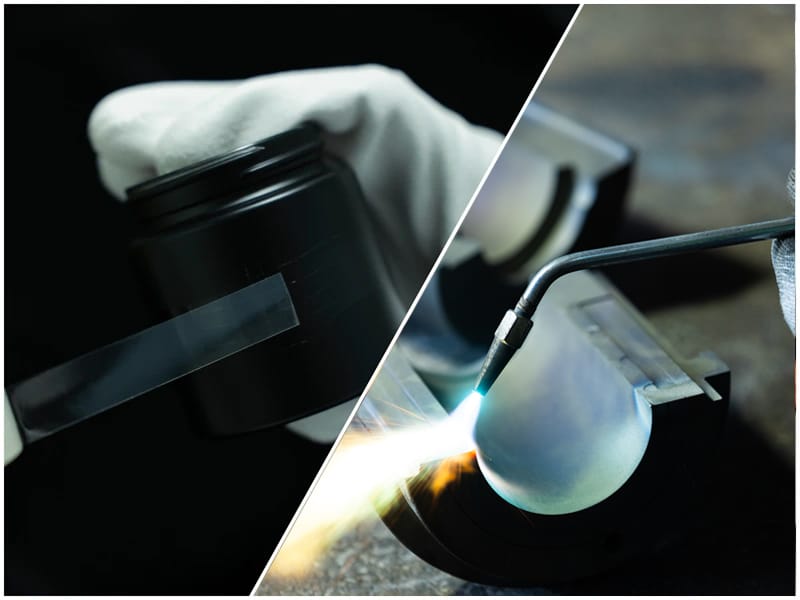

Mould designing and opening: Our engineers create molds based on approved design drawings to ensure that the final product fully meets the original concept.

Mass production: Through the glass blowing or injection molding processes, we can produce your glass jars in large quantities and maintaining the same high quality standards.

We can use processes such as spray coating, silk screen printing, hot stamping embossing and water transfer printing to highlight your brand and make your products stand out.

Our workers conduct 100% quality inspection to ensure that every glass jar that customers receive is satisfactory.

Packaging design: We offer customized packaging solutions, including luxurious packaging boxes as well as eco-friendly alternatives.

While ensuring smooth and timely delivery, we also pay attention to customer experience and satisfaction. Optimize every aspect of our operations based on customer feedback.

Glass guarantees superior fragrance preservation (zero interaction), conveys unmatched luxury, offers brilliant clarity for visual appeal, and provides exceptional chemical resistance to maintain scent integrity long-term.

We supply: Glass: Soda-lime

Customization: Molded & tubular shapes, diverse capacities (1ml – 500ml+), custom colors (pigmented glass, spray coating), extensive neck finishes (pumps, caps, droppers), and bespoke decoration.

Expertise in:Screen Printing: Durable logos & designs.

Hot Stamping: Metallic or foil accents.

Spray Coating: Soft-touch or pearlescent effects.

Etching/Frosting: Premium tactile finishes.

Vacuum Metallization: High-reflective chrome/gold plating.

Applied Color Labels (ACL): Vibrant, permanent graphics.

Precision engineering of neck finishes ensures perfect seal compatibility with industry-standard pumps, caps, and droppers. Our bottles undergo rigorous leakage testing and are designed for high-speed filling lines handling various viscosities.

MOQs are flexible, starting from 5,000 – 10,000 units for standard designs. Lower MOQs may be feasible for stock items or simpler decorations. We collaborate to find viable solutions for emerging brands.

Absolutely. Our glass complies with major international safety standards (FDA CFR 21, EU 10/2011, REACH, Prop 65) for direct fragrance contact. We provide necessary documentation to support your regulatory needs.

Yes. We provide:High-Post-Consumer-Recycled (PCR) glass options.

Lightweighting designs to reduce material use & shipping emissions.

Recyclable packaging.

Eco-conscious decoration alternatives (e.g., water-based inks).