Glass Cream Jar

Cream jars are more than just practical packaging; they’re powerful marketing tools for a variety of occasions, promoting skincare products in a visually appealing and practical way. Whether for daily use, gift giving, or limited-edition releases, these jars help shape brand image and boost customer satisfaction. Cream jars are widely used in daily skincare routines, particularly for moisturizing and nourishing the skin. They are designed to preserve product integrity, provide convenient application, and maintain hygiene. Whether for morning hydration or evening repair, cream jars play a crucial role in the effectiveness of skincare products. These jars can be customized with elegant designs.

Glass Cream Jar

Ideal for luxury skincare, face creams, and moisturizers, our collection features sophisticated designs, custom Finishes, secure preservation.

Customizing the Cream Jar Design Crafts to Enhance your Brand Identity

Transform your packaging into a masterpiece with our diverse design elements. From sleek finishes that exude elegance to vibrant accents like digital printing that demand attention, we turn ordinary storage jars into extraordinary brand statements. Add transparent windows for a sneak peek or magnified lens caps —each detail is crafted to captivate your product’s appeal.

Labeling

Pre-printed labels are attached to the bottle body, enabling complex colors and high-definition graphics. Suitable for rapid design changes and mass production.

Silkscreen Printing

The ink layer adheres to the surface, creating solid and patterns with a noticeable texture. Special effects (such as matte or raised finishes) can be achieved. It is wear-resistant and durable.

Spray Coating

Forms an even colored coating that completely covers and alters the original color and texture of the glass (matte/gloss). Offers rich colors and provides unique visual effects.

Frosting

Creates a matte texture on the surface, allowing light transmission while obscuring visibility. It feels smooth and delivers an elegant style. It is anti-slip and fingerprint-resistant.

Foil Stamping

Produces bright and luxurious metallic textures (such as gold or silver), offering strong visual impact. It is exquisite and eye-catching, suitable for luxury packaging.

Plating

Achieves a mirror-like metallic luster (such as chrome or rose gold). It provides a strong metallic, is wear-resistant, and corrosion-resistant. Long service life and enhanced aesthetics.

Process of Turning Your Ideas into Tangible Glass Cream Jar

1. Consultation & Sketches

Customer Consultation: YPC’s team will work with you to discuss your brand vision,product features, and market demands to ensure that the product can meet these requirements.

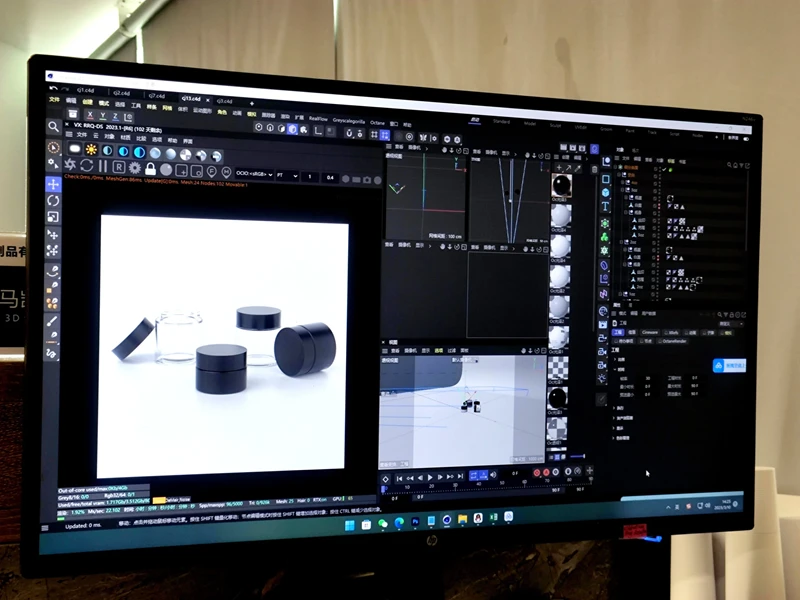

2. Design & 3D Modeling

Design optimization: We adjust the shape, size, and style, among other details, based on your feedback, in order to ensure that this bottle can showcase the unique charm of your brand.

3. Mold Creation

Mould designing and opening: Our engineers create molds based on approved design drawings to ensure that the final product fully meets the original concept.

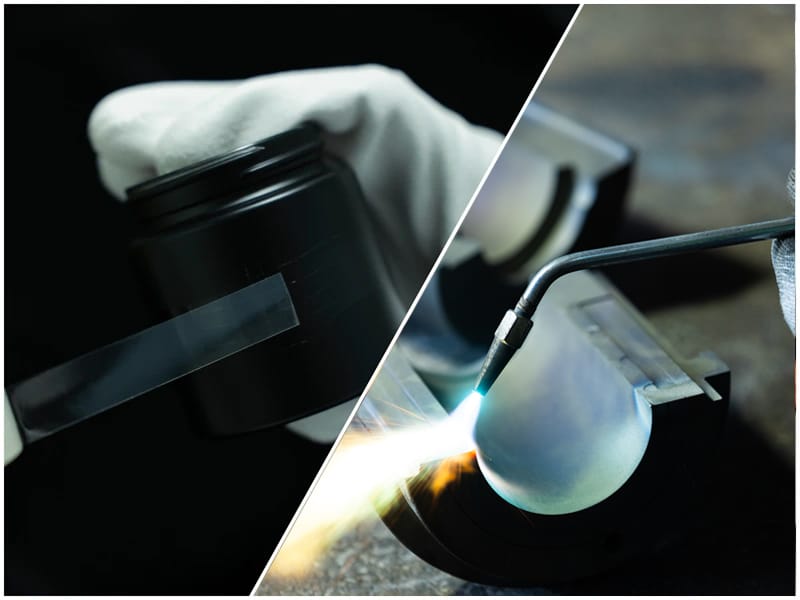

4. Production & Manufacturing

Mass production: Through the glass blowing or injection molding processes, we can produce your glass jars in large quantities and maintaining the same high quality standards.

5. Deep processing

We can use processes such as spray coating, silk screen printing, hot stamping embossing and water transfer printing to highlight your brand and make your products stand out.

6. Quality Control

Our workers conduct 100% quality inspection to ensure that every glass jar that customers receive is satisfactory.

7. Quality & packaging

Packaging design: We offer customized packaging solutions, including luxurious packaging boxes as well as eco-friendly alternatives.

8. Delivery & Satisfaction

While ensuring smooth and timely delivery, we also pay attention to customer experience and satisfaction. Optimize every aspect of our operations based on customer feedback.

Quality Control for Personal Care Glass Packaging

Learn More About Cream Glass Jar

What materials are used for the glass cream jars?

Crafted from premium super flint glass – offering crystal clarity, exceptional strength, and reliable breakage resistance to perfectly preserve your formulations.

Can you customize the design of the glass cream jars?

Full customization available-collaborate with our designers to craft bespoke jars in your choice of dimensions, hues, and finishes for seamless brand alignment.

How can I ensure the quality of my custom cream jars before placing a bulk order?

Precision sampling protocol: Design approval → 3D prototype → physical glass verification — guaranteeing exact specification compliance.

Are the glass cream jars eco-friendly?

Sustainable by design – our premium glass jars are endlessly recyclable and crafted for reuse, delivering eco-luxury packaging.

What is the MOQ for custom glass cream jars?

Stock items: No MOQ

Custom designs: MOQ varies by specification.

How long is the delivery time for custom cream jars?

The general delivery time is 25 to 30 days. The exact time will depend on the customized project.

Can I get a sample before placing a bulk order?

Yes, we provide samples for your review and approval before you place a bulk order to ensure the product meets your expectations.