THC Oil Glass Bottle

THC (tetrahydrocannabinol) oil, a concentrated form of cannabis, requires specialized packaging to maintain its quality and ensure consumer satisfaction. Glass bottles have emerged as the packaging of choice for THC oil products, offering a combination of aesthetic appeal, robust protection, and compliance with industry standards.

THC Oil Bottle

Choosing the right type and size of glass bottle depends on the specific THC oil product, the intended use, and any applicable regulations.

30ml Rectangle Glass Tincture Bottle with Natural Bamboo Dropper Cap | For CBD Oil, Herbal Tinctures & Essential Oils

30ml Rectangle Glass Tincture Bottle with Child Proof Cap | for CBD Oil, Herbal Tinctures & Essential Oils

30ml Rectangle Glass Tincture Bottle with Child Proof Cap | For CBD Oil, Herbal Tinctures & Essential Oils

30ml UV Protective Black Glass Tincture Bottle with Child Proof Cap | For Light-Sensitive CBD Oil, Essential Oils & Herbal Extracts

15ml Glass Tincture Bottle with Child Proof Cap | Matte Blue Color | For CBD Oil, Herbal Tinctures & Essential Oils

1oz (30ml) Frosted Glass Tincture Bottle with Child Proof Cap | Amber & Cobalt Blue | For CBD Oil, Herbal Tinctures & Drops

Superior Solutions by Expert THC Oil Bottle Supplier

Available Caps

Child Resistant Closures: Child-resistant (CR) caps are essential for THC oil bottles, meeting strict cannabis regulations by preventing child access while maintaining adult usability.

Tamper-evident + Child Resistant Closures: Child-resistant, tamper-evident caps help THC oil bottles meet safety regulations while assuring product integrity.

Child Resistant Dropper: CR droppers come as complete sets (cap, bulb, pipette) designed for specific bottle necks.

Tamper-evident + Child Resistant Dropper: Some CR dropper caps include tamper-evident bands that break upon first opening, adding security and verifying product integrity.

Popular Colors

Clear: Allow the product to be fully visible, enabling consumers to inspect the oil’s consistency and color. This transparency can build trust with consumers.

Amber: Effectively block up to 99% of harmful UV and visible light,helps maintain the purity and potency of the oil for longer storage periods

Blue: Offers a moderate level of UV protection, evoke a sense of luxury and calmness, aligning with certain brand identities.

Frost: Frosting provides a translucent, matte finish that can be achieved through various processes, primarily acid etching, or spray coatings.

Spray Coating Color: A highly effective way to enhance the packaging of THC oil, offering a blend of aesthetic appeal, product protection, and branding versatility.

Available Shapes

Round Bottle: The most classic and widely used glass bottle shape. They feature a cylindrical body with rounded shoulders that taper into a narrow neck.

Flask-shaped Bottle: Typically feature a flattened or rectangular body with a narrow neck, The distinct shape provides a unique canvas for branding and labeling.

Flat Shoulder Bottle: Flat shoulder glass bottles are a distinct and popular choice for packaging THC oil, offering a blend of modern aesthetics, efficient labeling space, and practical functionality.

One-stop Customization Service

We take pride in our diverse and proven processing technologies as a custom glass container manufacturer. From frosting and silkscreen to metallization, lacquering, hot stamping, and tinting.Take a look at the introduction of each technique to help you make an informed decision when considering custom CBD dropper bottles.

Labeling

Pre-printed labels are attached to the bottle body, enabling complex colors and high-definition graphics. Suitable for rapid design changes and mass production.

Silkscreen Printing

The ink layer adheres to the surface, creating solid and patterns with a noticeable texture. Special effects (such as matte or raised finishes) can be achieved. It is wear-resistant and durable.

Spray Coating

Forms an even colored coating that completely covers and alters the original color and texture of the glass (matte/gloss). Offers rich colors and provides unique visual effects.

Frosting

Creates a matte texture on the surface, allowing light transmission while obscuring visibility. It feels smooth and delivers an elegant style. It is anti-slip and fingerprint-resistant.

Foil Stamping

Produces bright and luxurious metallic textures (such as gold or silver), offering strong visual impact. It is exquisite and eye-catching, suitable for luxury packaging.

Plating

Achieves a mirror-like metallic luster (such as chrome or rose gold). It provides a strong metallic, is wear-resistant, and corrosion-resistant. Long service life and enhanced aesthetics.

Process of Turning Your Ideas Into THC Oil Glass Bottle

1. Consultation & Sketches

Customer Consultation: YPC’s team will work with you to discuss your brand vision,product features, and market demands to ensure that the product can meet these requirements.

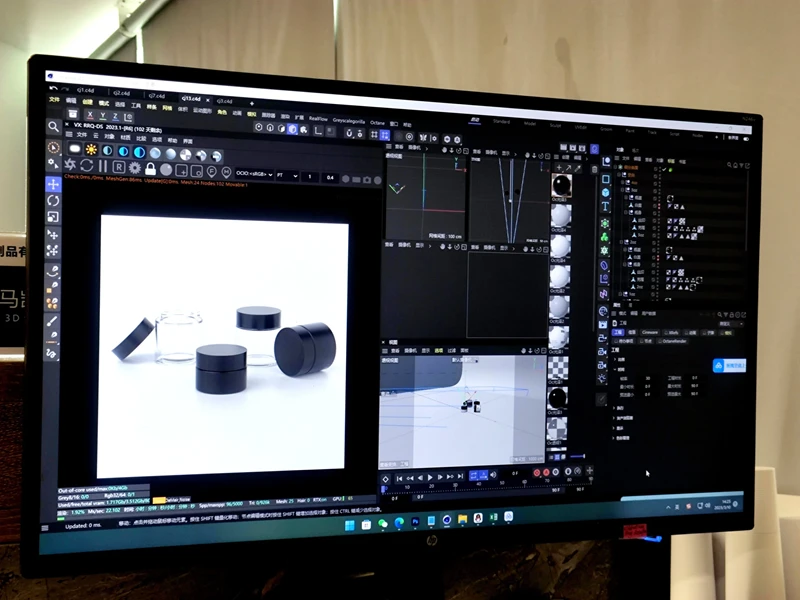

2. Design & 3D Modeling

Design optimization: We adjust the shape, size, and style, among other details, based on your feedback, in order to ensure that this bottle can showcase the unique charm of your brand.

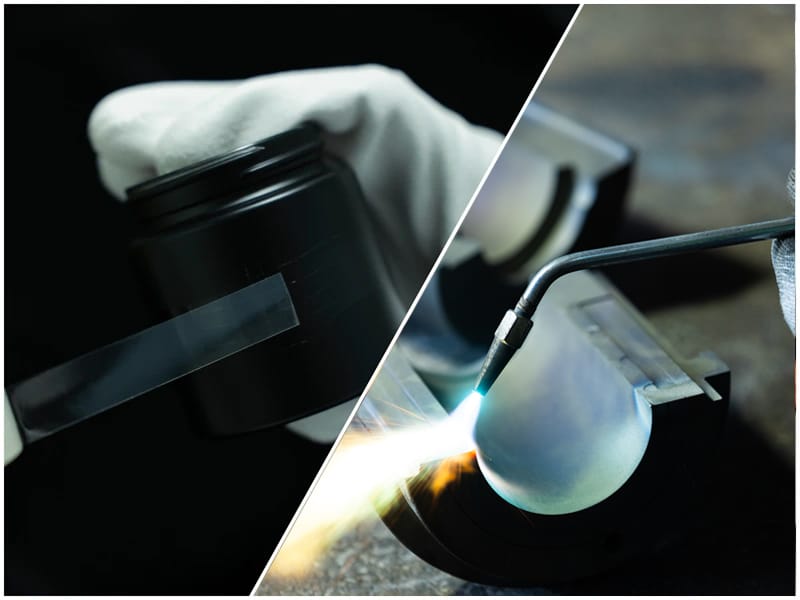

3. Mold Creation

Mould designing and opening: Our engineers create molds based on approved design drawings to ensure that the final product fully meets the original concept.

4. Production & Manufacturing

Mass production: Through the glass blowing or injection molding processes, we can produce your glass jars in large quantities and maintaining the same high quality standards.

5. Deep processing

We can use processes such as spray coating, silk screen printing, hot stamping embossing and water transfer printing to highlight your brand and make your products stand out.

6. Quality Control

Our workers conduct 100% quality inspection to ensure that every glass jar that customers receive is satisfactory.

7. Quality & packaging

Packaging design: We offer customized packaging solutions, including luxurious packaging boxes as well as eco-friendly alternatives.

8. Delivery & Satisfaction

While ensuring smooth and timely delivery, we also pay attention to customer experience and satisfaction. Optimize every aspect of our operations based on customer feedback.

Quality Control for THC Oil Glass Bottle

Learn More About THC Oil Glass Bottle

What are the main advantages of using glass bottles for THC oil?

Glass bottles maintain THC oil purity by being chemically inert, airtight, and UV-protective (especially amber/opaque types). They also offer premium appeal while being eco-friendly and reusable.

What are the common sizes of THC oil glass bottles?

THC oil glass bottles come in various sizes, typically expressed in milliliters (mL) or ounces (oz). Common sizes include 10mL, 15mL, 30mL, and 60mL (corresponding to 0.5oz, 1oz, and 2oz).

Are THC oil glass bottles child-resistant?

Yes, many THC oil glass bottles, especially those used for tinctures, are paired with child-resistant (CR) caps or dropper assemblies.

How long does THC oil typically last when stored in glass bottles?

When stored properly in a cool, dark place and protected from air and light, THC oil in glass bottles can maintain its potency and quality for between one and two years.

Why are child-resistant (CR) and tamper-evident (TE) features important?

CR and TE features are often legally mandated for THC products to ensure safety and prevent accidental ingestion by children.

What materials are commonly used for the droppers in THC oil glass bottles, and are there any potential interactions with the oil?

THC oil droppers combine a chemically inert glass pipette (for purity) with a silicone/natural rubber bulb (for squeeze function). Silicone offers superior chemical resistance for high-purity applications.

What is the significance of bottle color for THC oil?

Amber and opaque bottles offer superior UV protection for THC oil, preventing degradation better than blue/green/clear glass.